CNC Monitoring System

Problem

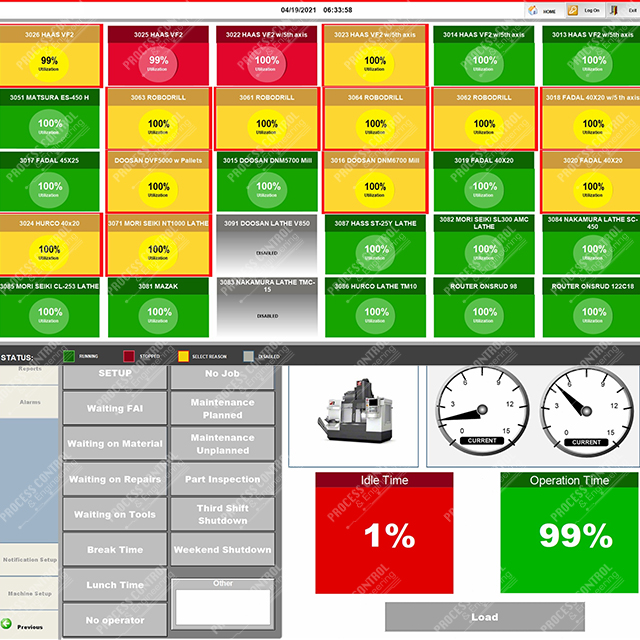

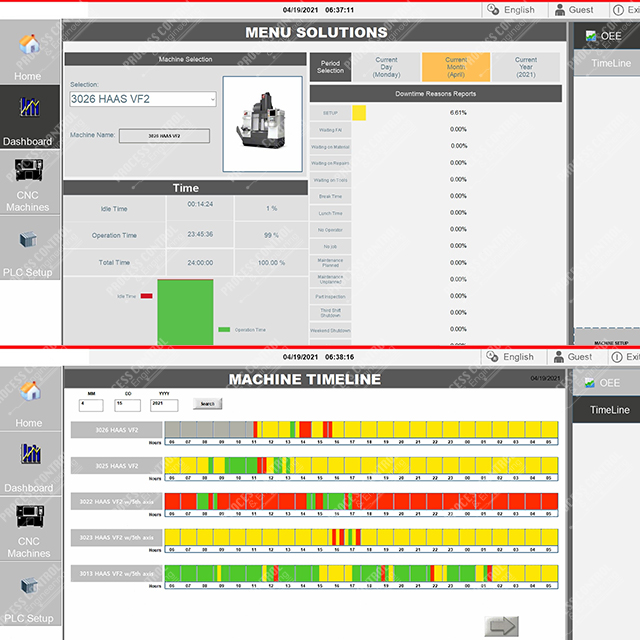

The customer needs a monitoring system that tracks CNC machines statuses and report causes of downtimes. Also, the system is required to provide tools like charts and raw data for further analysis reports, and built with a user-friendly interface that will show all the data in mobile and desktop devices.

Solution

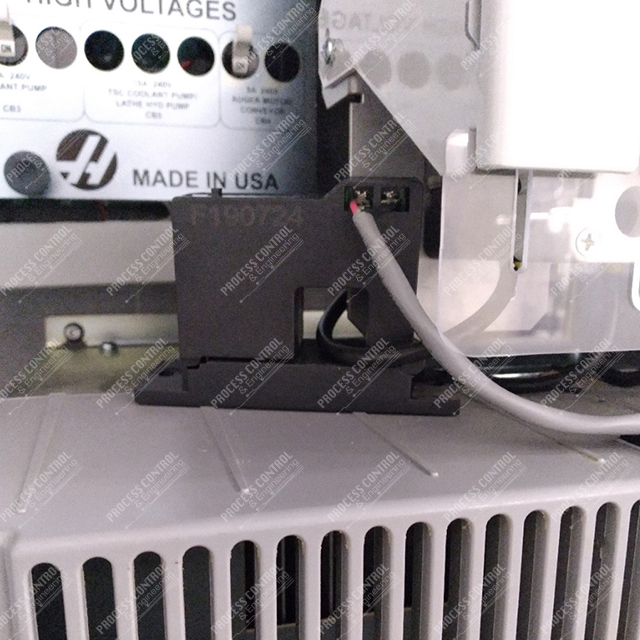

PC&E engineering team designed a non-invasive SCADA system which collects all the data from each machine based on the current consumption. In this way, the implementation would be faster and do not compromise the production at any moment.

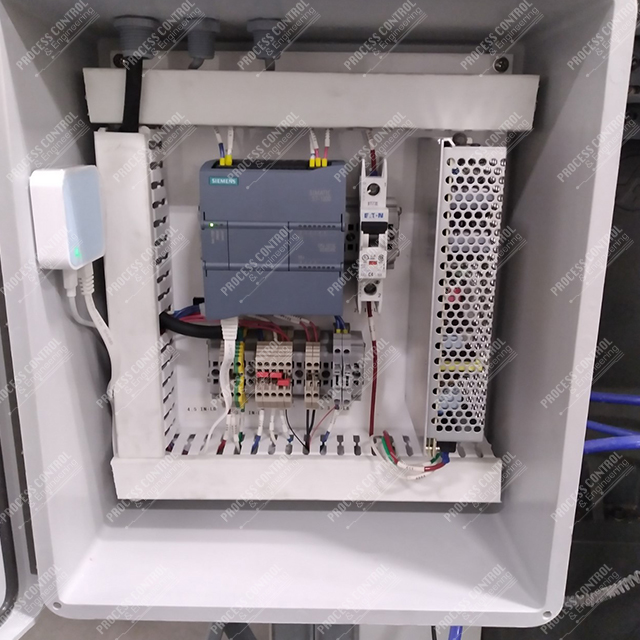

A small Siemens PLC would be in charge of reading the current of each machine and send the data every certain period of time. The data is received by the server, processed and stored in a SQL database.

Information, charts and reports are displayed on any device within the internal network and restricted according to the user access level (the information can be edited only by administrators).

Duration

About 4 months

Services Provided

- Control Engineering & Design

- Panel Construction

- PLC & HMI Programming

- Start-up & Commissioning

Technology Used

- Ecostruxure Machine SCADA Expert

- SIEMENS S7-1500 PLC

- OPC UA Connection

- SQL Server

- HTML

- Machine SCADA Mobile Access

Start-up