3D Printing System

Problem

Our customer asked us to design and implement a complete 3D impression system for printing homes.

Some of the requirements were that it has to be a fully automated system and implement machine safety.

Solution

The PC&E team designed a large 3D printing system consisting of a robot with an extruder to melt PET G pellets, a safety barrier with a safety light curtain to provide protection for those in the work area.

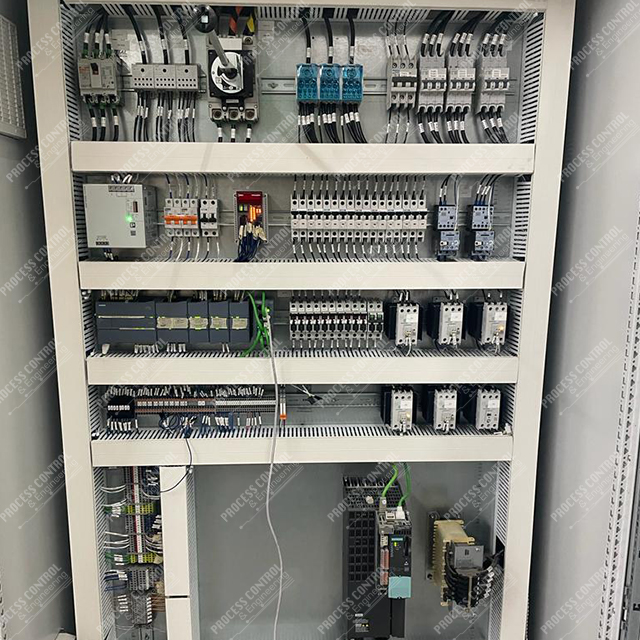

Which includes a main control cabinet that contains the PLC, CB and other control components; as well as an auxiliary control cabinet with HMI and Emergency Stop for supervision.

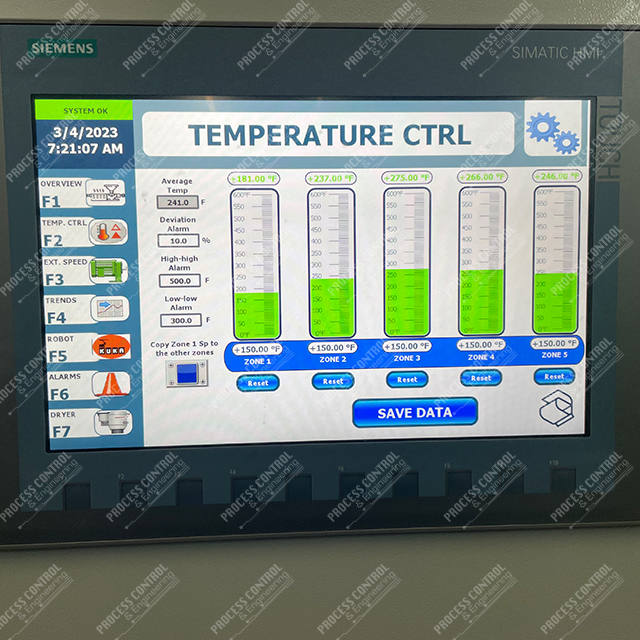

The control system for the extruder machine uses a SIMATIC S7 1200 PLC with I/O modules to control the temperature. And the HMI allows the operator to monitor and control parameters of the machine.

Duration

2160 Hours

Services Provided

- Mechanical Design

- Electrical Design & Schematics

- PLCs & HMIs Programming

- Motion Control Programming

- Robot Programming

- Machine Safety

- Start up & commissioning

Technology Used

- KUKA Robot

- Siemens S7-1200

- SIMOTICS S motors

- Extruder

Start-up