Vision System On Delta Machine

Problem

Our client, an important manufacturer and marketer of medical devices for professional use across a wide field of clinical applications all over the U.S. requires a system for visual inspection of parts.

Solution

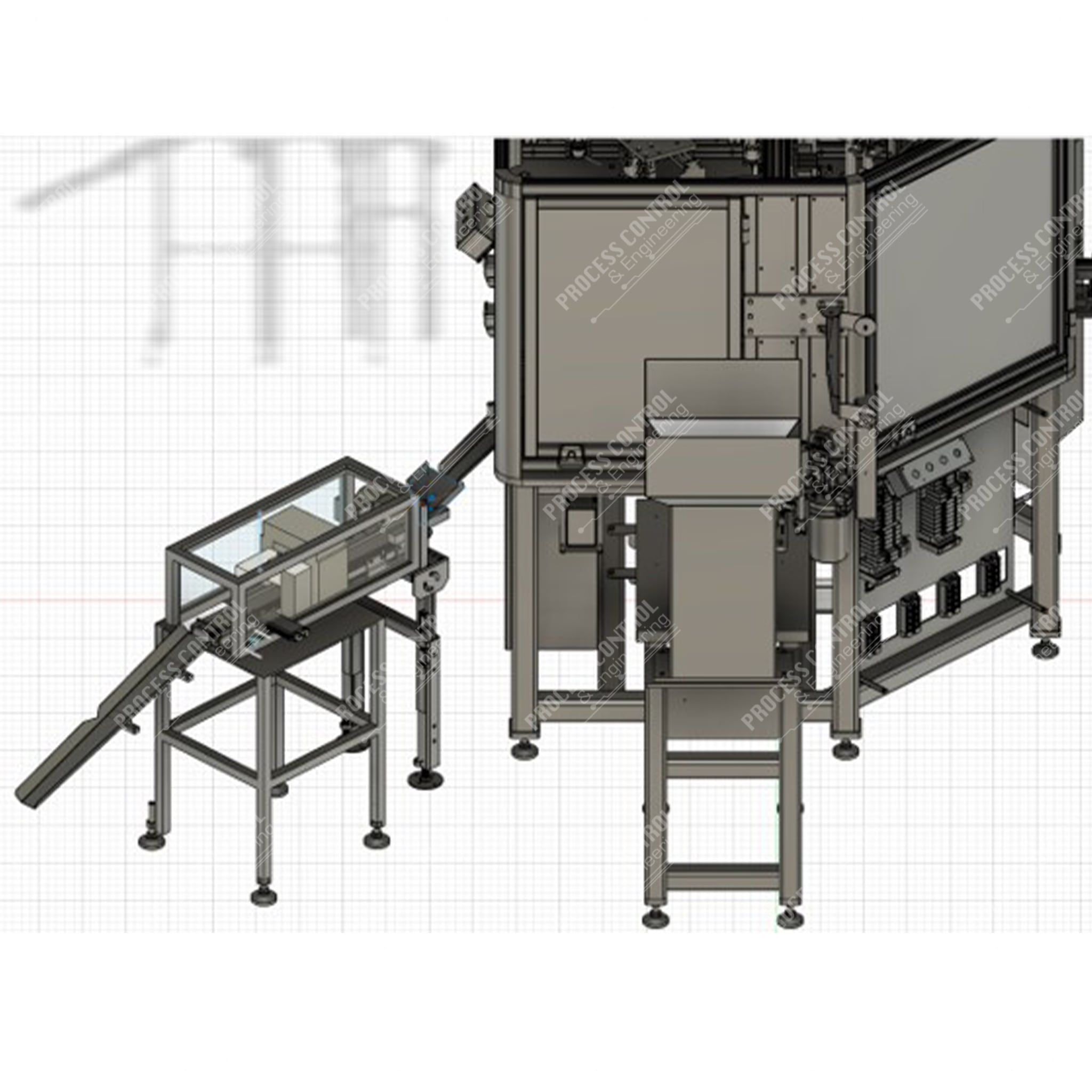

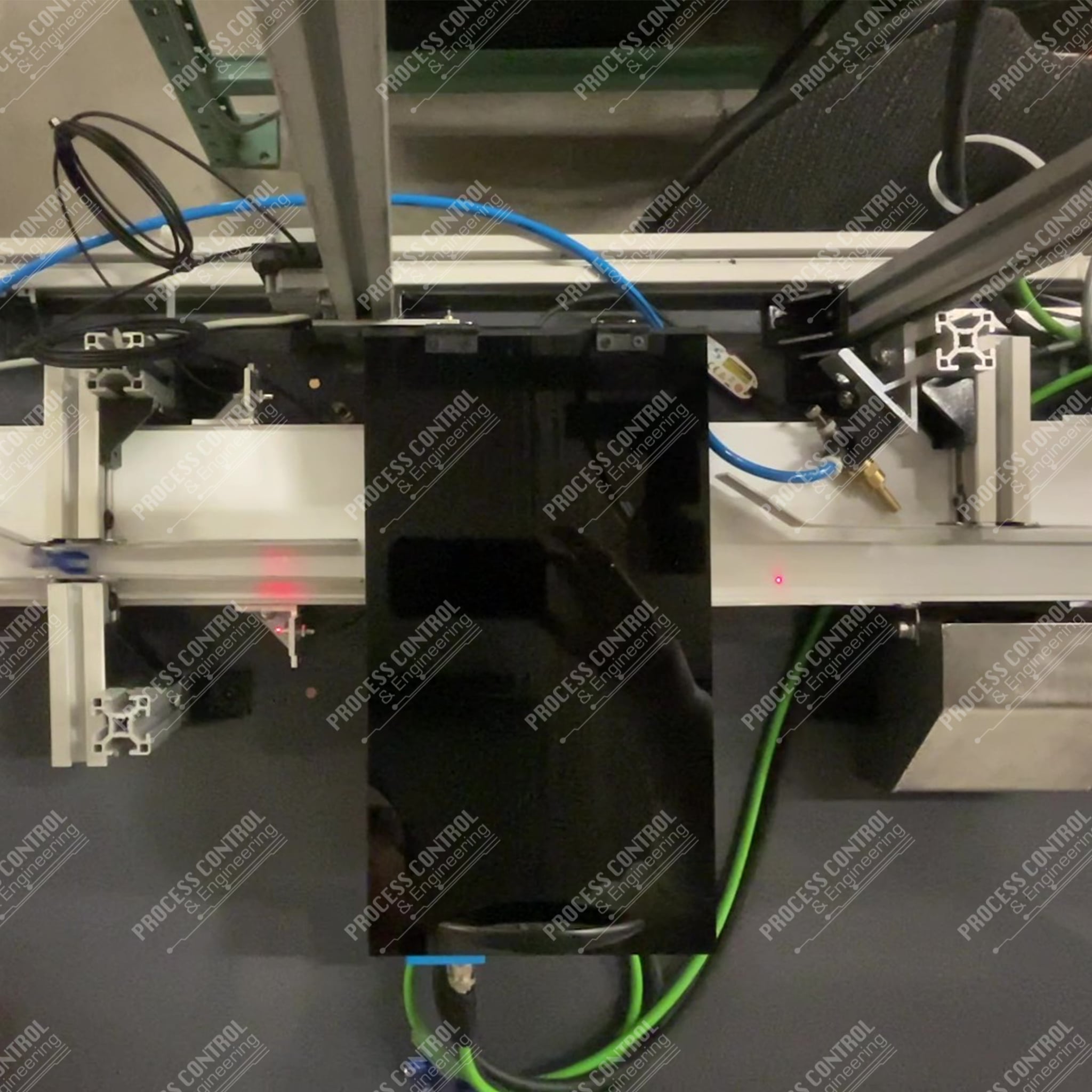

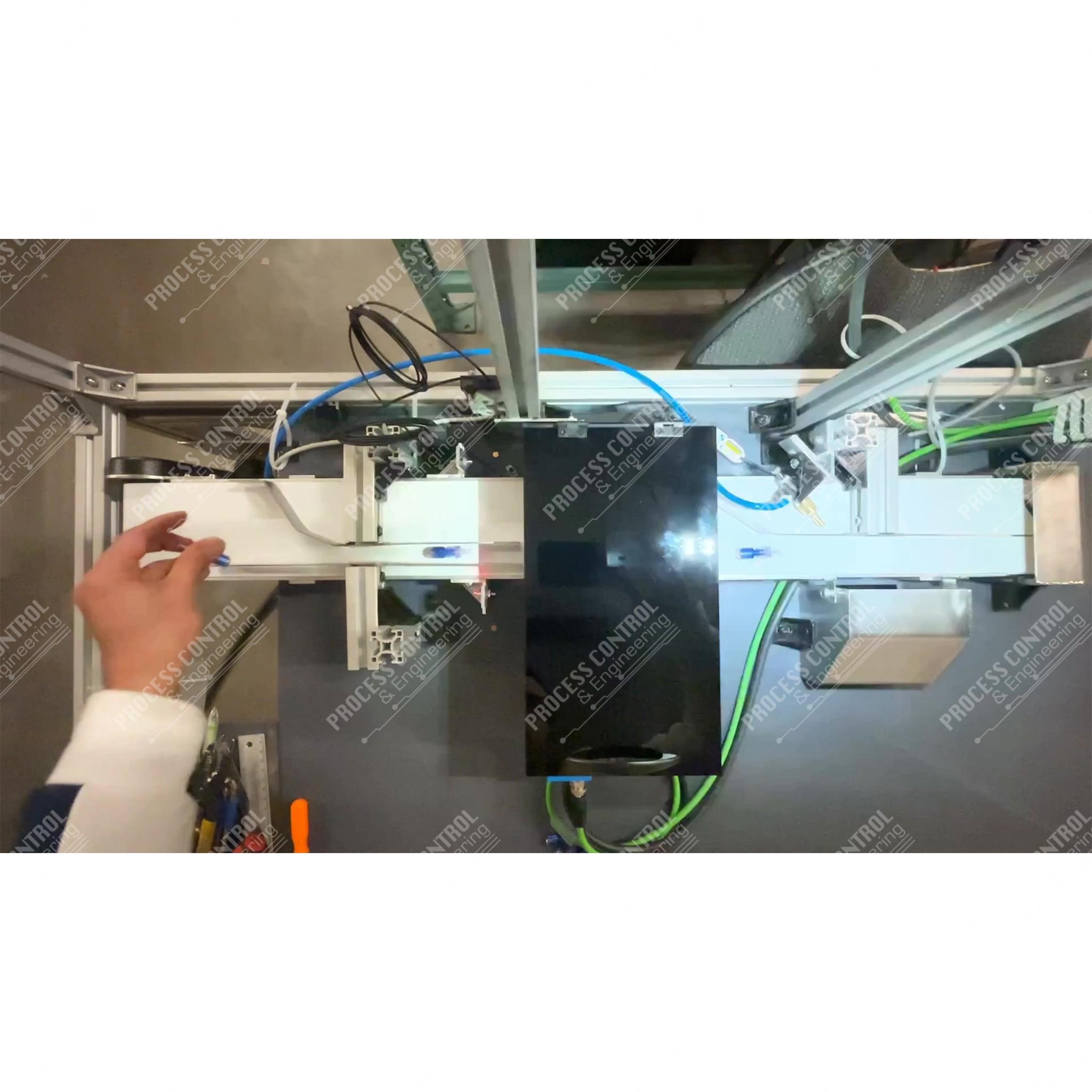

PC&E developed an automatic machine for visual inspection, which tests the overall dimensions of the part and the presence of glue in the right area. Combining artificial intelligence (AI) with a Vision System, it automates assembly verification, and defect detection, and classifies each part as Good/Defective.

The entire system consists in:

- Stainless Steel Funnel

- Conveyor for Visual inspection

- Visual System Checkbox

- Mechanical switch device to separate the rejected parts.

Duration

2016 Hours

Services Provided

- PLCs Programming

- Installation & Connections

- Vision System Programming

- Electrical Design & Schematics

- Mechanical Schematics

Technology Used

- SIEMENS S7-1200 PLC

- FESTO Vision System

- SIEMENS WinCC Software

Start-up