Robotic Milling Cell

Descripción del Problema

In response to the increasing demand for efficiency and precision, our client sought to modernize their manufacturing process for life-size bronze statue molds.

The 1.5 x 1.5 x 3-meter Styrofoam blocks, which were previously machined manually and through a 3-axis CNC process, required a more advanced and efficient solution.

Solución Brindada

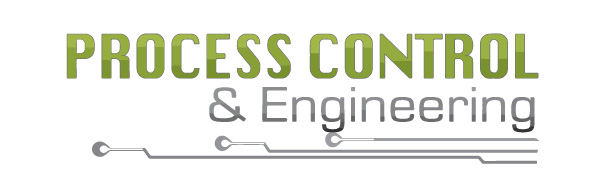

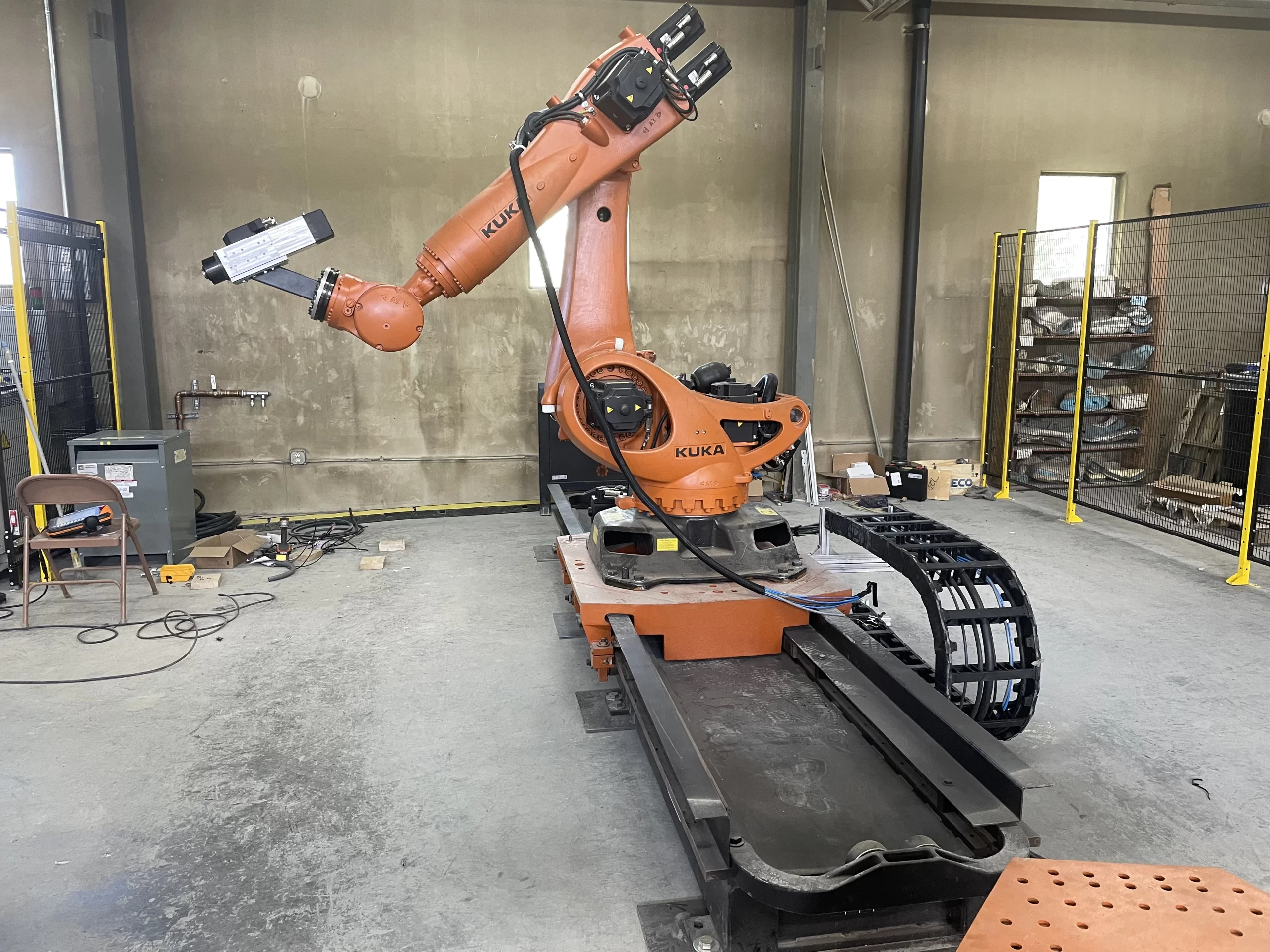

Our proposal materialized in the design, manufacturing, and installation of a state-of-the-art robotic cell, optimized for machining Styrofoam blocks in 8 axes. For this purpose, we selected a KUKA robot with a reach of 2.7 meters, mounted on a linear axis with a 2.5-meter trajectory.

The robotic cell was designed considering two key machining areas. The first area incorporates a rotating table that functions as an eighth axis, allowing 360° machining in significantly reduced time. The second area consists of a fixed table measuring 3 meters in length, providing the necessary capacity for the fabrication of generously sized pieces.

Duration

2160 Hours

Services Provided

- Mechanical Design

- Electrical Design & Schematics

- Motion Control

- Robot Programming

- Safety Machine

- Start Up & Commissioning

- Robotic Cells

Technology Used

- KUKA Robot

- Turntable

- Setter & Tool Changer

- Spindle

- SPRUTCAM System

Start-up

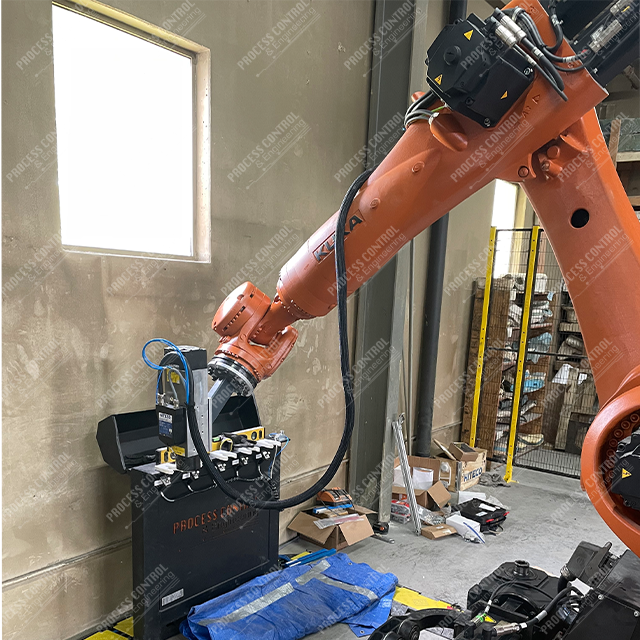

Tool Changer

In order to avoid interrupting the process, the robotic cell has the capability to exchange its tool on its own. Once the process with a tool is completed, it will move to the rear where the other tools are located. It will arrange and release the tool in its respective place, choose the next tool using a suction method, and then proceed with the ongoing process.