Robot Weld Seal Liner Safety Installation

Problem

The customer required a complete security system to cover a work area of 4 welding stations, where each station performs a different function and due to the security vulnerabilities found, a change in the system was necessary.

Solution

Based on the client’s needs, an analysis of our client’s security systems was performed, reaching the conclusion with PC&E’s engineering team to completely redesign a security system where the main feature is that any person who tries to interfere in the work area of any of the stations will stop their functions to avoid any accident that may happen.

Among the main safety elements installed are Safety Mats, Light Curtains, Interlocks, E-stops and Safety Controls, making this a safe place for workers.

As long as everything is working properly, e-stops were installed around the structure containing the stations in case of an emergency to stop the process as soon as possible.

Duration

5 weeks

Services Provided

- Machine Safety

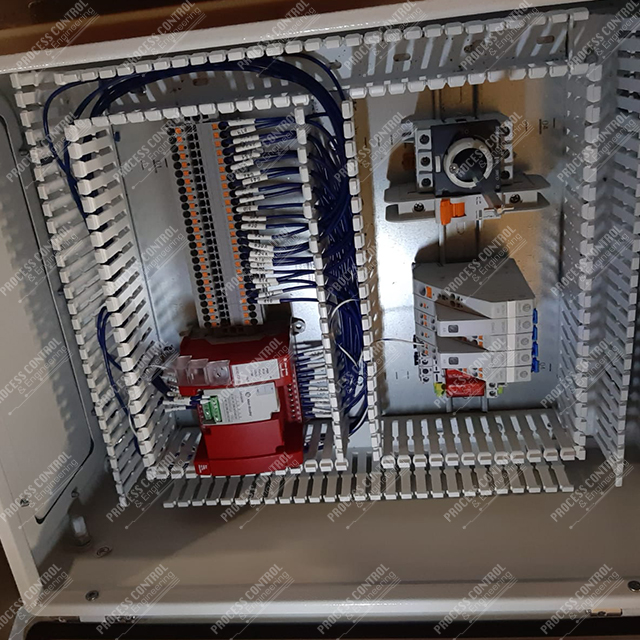

- Panel Construction

- Safety System

- Electrical Design & Schematics

Technology Used

- Safety Controller

- E-Stops

- Safety Mat

- Curtains Lights

- Interlocks

Start-up