Excess Material Removal Station

Problem

The client needs to eliminate excess material during the manufacturing of parts, which is done through upset forging. The excess material generates unsafe conditions when handling pieces, which may result in injury or death to the operators.

Solution

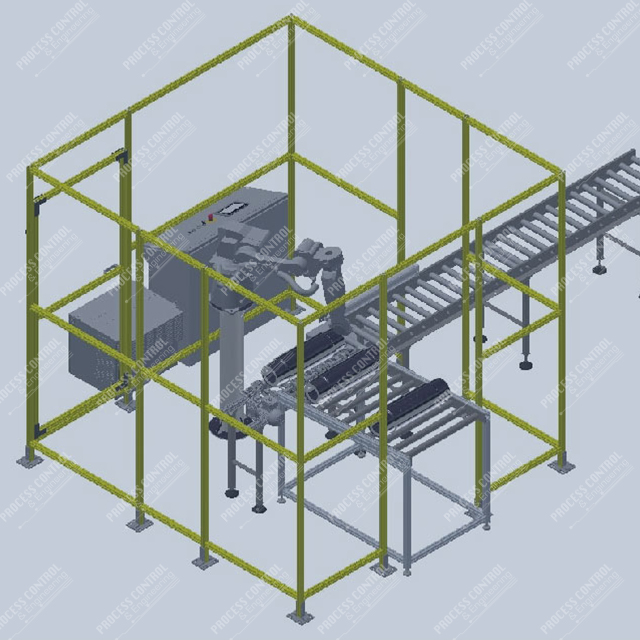

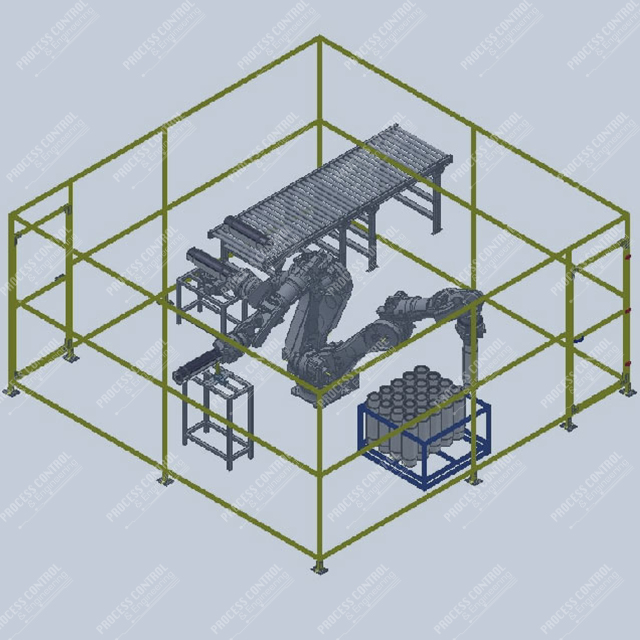

The new automated machining station consists of a transfer table with an implemented Keyence system that positions parts in a way that allows the robot to take it and identify any surplus material. If any excess material is present, the robot will place the part in a plasma system, remove said material, and deposit the part in a rack.

Duration

About 19 weeks

Services Provided

- Control Engineering

- Mechanic & Electric Design

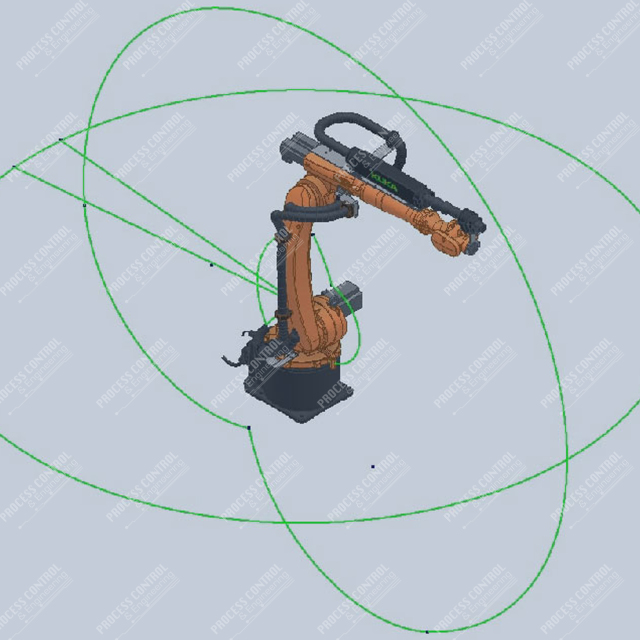

- Robotic Programming

- Vision System Programming

- PLC & HMI Programming

- Security System Programming

- Robot Installation

- Mechanical assembly of plasma cutting system

- Electrical Installation

- Start-up & Commissioning

Technology Used

- KUKA Robots

- SIEMENS S7-1500 PLC

- SIMATIC Comfort Panel TP700

- Visual System

- Safety Laser Scanners

- PROFINET Communication

- Inventor 3D Drawings

Start-up