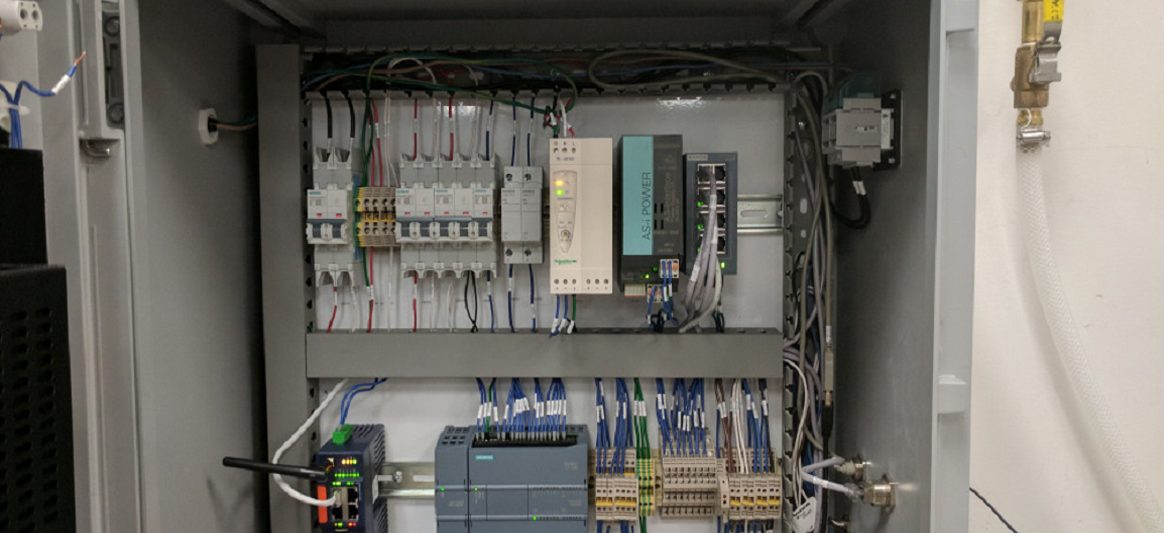

DUAL GAS CONTROL SYSTEM

Description:

Gas System Control Injection for 3 extruders. Each extruder will have only one gas (Nitrogen). The control is based on PLC logic and HMI including trends of pre-selected variables, change log, historical data log, user administration, and system setup screens.

The HMI configuration is as follows:

- Main Menu screen (Administrator, supervisor and operator Menu)

- System information screen

- User Administration screen

- Active alarms screen

- Historic alarms screen

- Active warnings screen

- Historic warnings screen

- Date and Time configuration screen

- Clean screen function

- System Shutdown function

- Main Menu screen (Administrator Menu)

- Analog input configuration screens

- Analog output configuration screens

- Recipes configuration screen

- System Diagnostics screen

- Extruder A settings screen

- Extruder A PID setup screen

- Extruder B settings screen

- Extruder B PID setup screen

- Extruder C settings screen

- Extruder C PID setup screen

- Mu-Talc configuration screen

- Overview screen

- Extruder A Gas System Control screen

- Extruder B Gas System Control screen

- Extruder C Gas System Control screen

- Trends screens:

- Actual gas concentration of gas in each extruder

- Postmeter pressure vs actual output of each extruder

- Postmeter pressure vs actual flow rate of each extruder

- Actual gas concentration vs delivery pressure of each extruder

- Actual extruder speed vs delivery pressure of each extruder

- Auxiliary output percentage vs delivery pressure of each extruder

- Actual GP speed vs extruder pressure of each extruder

- Change Log screen

- Summary screen

- Cameras screen