Thermoforming control

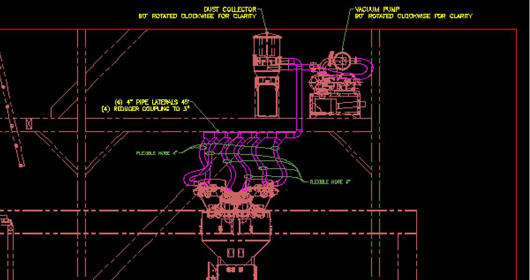

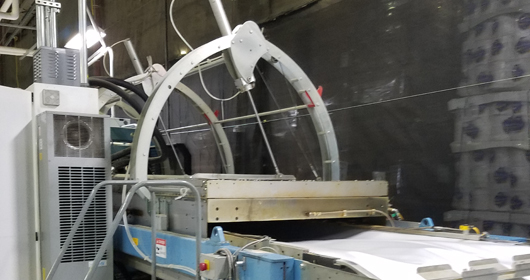

After assessing the needs of the client, PC&E develops a new control system for the Thermoformer, which includes heaters, machine controllers, and a new operator interface. Engineers at PC&E upgrade the existing trim press controls to communicate with the Thermoformer. Communications between the Thermoformer panels and the Trim Press panels are accomplished via Ethernet IP deterministic digital network. PC&E develops the HMI to mimic operator functions found on other machines by the same manufacturer, ultimately reducing the learning curve for set up and operation personnel.

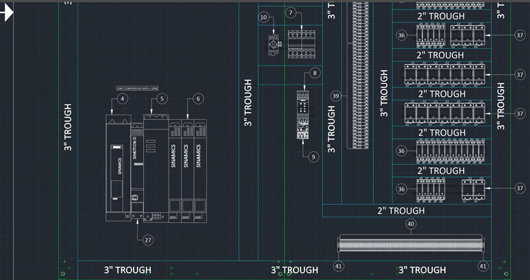

This automation control solution included four Siemens 5 motors and drives, a Sinamics machine controller, and an industrial military grade PC. These components were uniquely chosen by application engineers at PC&E to provide the most effective and reliable solution to the client’s individual automation challenges.

An Allen-Bradley industrial PC with a Windows operating system can be utilized for user-friendly, menu based color displays and graphics to guide operators and maintenance personnel through all the functions of the machine. This high speed PC provides virtually unlimited storage of product recipes, trending and SPC data, as well as the ability to operate Microsoft Office or equivalent products for manuals, maintenance logging procedures and data acquisition. National Instruments Lookout Software easily manages the machine’s HMI communication and its features are easy to expand in the future. Password protection, Ethernet, USB and online diagnostics are all provided for an efficient, maintainable and secure system.